MComP™

Micro/Nanocomposite Metals

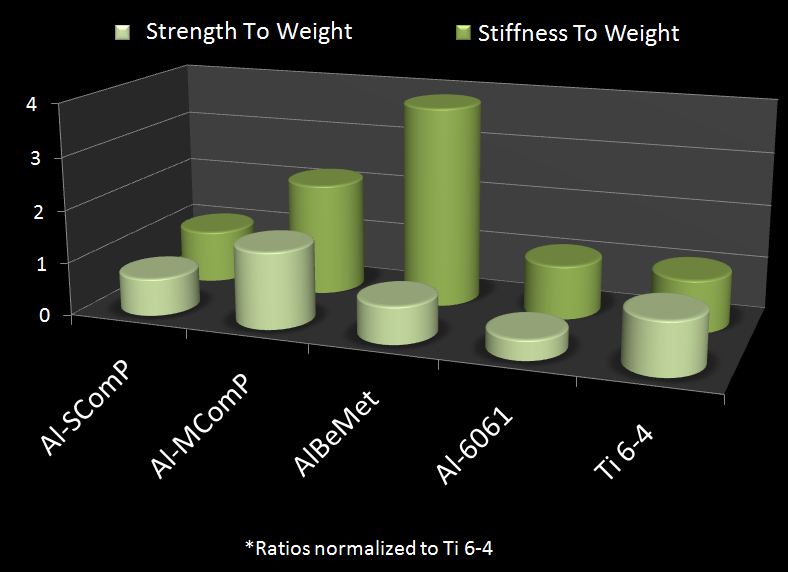

MComP™ (Micro/Nanocomposite) hierarchically-structured super metals offer very high strength-to-weight ratios in magnesium and aluminum alloys. Powdermet offers services for mechanical alloying of micro- and nano-metallic systems including nano-Al, and nano-ceramic additions to metallic alloys. Nano/microstructures are of great interest due to their duplex structure, giving better than rule of mixture properties, enabling very high strength, yet still ductile metallic systems, using Al, Mg, Ti, Fe and other base materials.

AlLiB-MComP™ is a traditional metal matrix composite that is created using powder metallurgical techniques combining aluminum with two other lightweight and high specific stiffness metals: boron and lithium, at the nano-level. The combination of these lightweight (lithium 0.5g/cc) and high modulus (boron E=400GPa) reinforcements allow Powdermet to greatly exceed standard aluminum properties by a nanoengineering process and still retain the weight savings that the lithium gives the alloy.

These powder metal parts are mechanically alloyed, canned and then consolidated to 80% density. Final consolidation is performed using extrusion, rolling and quasi-isostatic forging to produce the final part at a density of 2.5g/cc. The final parts can be annealed or aged and are available in rod, bar, tube, plate, sheet and some near-net and net shape parts.

MComP™ Advantages: