Insalloy™

The practical response to your most demanding energy-absorption and thermal-load conditions

Insalloy™ is a patented thermally insulating, high temperature performance, syntactic metal composite alloy.

Insalloy combines the thermal properties of refractory ceramics with the mechanical properties and fabricability of metals, such as ductility and ease of attachment. Insalloy is weldable, brazeable, and boltable. Due to it’s unique composite structure, Insalloy has reduced thermal conductivity, thermal expansion, density, and modulus compared to pure metals— providing tremendous resistance to thermally induced buckling encountered in high temperature, structurally-demading environments.

Due to these attributes, Insalloy insulating metal composites negate the problems typically found with the creation of thermally stressed structures such as hypersonic vehicles, engines, and thermal energy storage systems. Furthermore, Insalloy composite metals can be fabricated from a range of metals, including magnesium and aluminum alloys for cryogenic applications, titanium, iron, and nickel based alloys for temperatures of 650-1100C, and niobium, molybdenum, and other refractory metal alloys for temperatures of 1200-1700C+.

In the design and fabrication of high temperature structures, designers have a choice between cost prohibitive exotic material hot structures, and complex insulated cold structures (which are both difficult to assemble and seal). Utilizing Insalloy as a structural insulator in lined or insulated systems overcomes these difficulties, along with the parasitic weight associated with traditional systems. In the case of molten salt thermal storage systems this means reduced assembly and sealing costs and extended life compared to refractory lined vessels, and also reduced insulation needs for hot structures. In applications ranging from hypersonic vehicles to cryotanks, parasitic weight is again eliminated while thermal stresses are reduced by up to 80% over other hot structure materials.

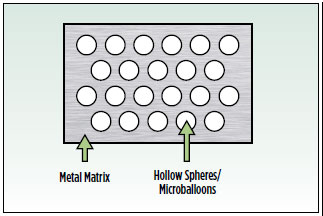

Insalloy’s unique structure is a space-filling, array of hollow, micron-sized insulating microspheres embedded in a heatresistant, ductile, durable metal matrix. This lightweight structural syntactic is unique in its ability to function effectively despite the extreme thermophysical and highly corrosive properties, such as in solar salt applications.

Insalloy can be fabricated in traditional metal forms, including iso-grid, L-stiffened panels, plate, rod, tube, and sheet form. As noted, it is also easily bolted, threaded, brazed, and can even be welded for assembly. Depending on the alloy, wrought, rolled, and extruded product can be readily produced, or net shape powder metallurgy or cast shapes can be created.

As compared to metal alternatives, Insalloy metal composites exhibit:

In hot structure applications, these properties lead to:

These features result in performance improvements, including: